Traditional Purlin Roof Construction

3 lean to roofs less common.

Traditional purlin roof construction. A truss roof using factory made trusses which are delivered to site complete and just erected. The longitudinal horizontal beam that is sitting on a post or the principal rafter of a truss and used to support common rafters. Traditional roofs work by distributing loads from the rafters down through to the wall plate and then through to the walls below. Parts of a traditional queen post roof truss.

A cut roof this is the traditional method of cutting the timber on site and building up the roof using rafters ridge boards joists and purlins etc the exact details being determined by the size of roof size of timbers etc. Purlin in architecture structural engineering or building a purlin or historically purline purloyne purling perling is any longitudinal horizontal structural member in a roof except a type of framing with what is called a crown plate. Purlin plate principal purlin and common purlin. There are two basic methods of pitched roof construction.

Every member of a traditional cut roof is individually cut and assembled on site. Exposed rafters are a feature of some traditional roof styles. Once the purlins are in place the panels can be craned in in a matter of minutes. The overall construction of a traditional cut roof is to ensure that the load of the roof is evenly transmitted to the walls below.

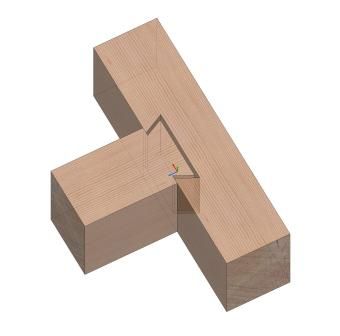

In architecture or structural engineering or building a purlin or purline is a horizontal structural member in a roof. The best way to transfer load is with a timber to timber joint a compression fixing. The rafters are the main load bearing elements of the roof. A common arrangement is a rafter and purlin system which combines purlins and rafters.

Purlin plates under purlin principal purlins and common purlins. It is a very common form of construction. This is a large timber running at right angles to the rafters and usually positioned mid span. The use of purlins as opposed to closely spaced rafters is common in pre engineered metal building systems and both the ancient post and beam and newer pole building timber frame construction methodologies.

There are three types of purlins in wood construction. In traditional timber framing there are three basic types of purlin. They span from the wallplate to the ridge board providing a platform for the underlay battens and tiles. The beams will typically be placed along the ridge at the eaves and halfway between the two where they are known as purlins.

In traditional construction spans of over 3 metres or so were often dealt with by adding a purlin. Nails bolts and screws create a mechanical fixing to stop uplift through wind etc. Sips panels these panels are from sipco need to be craned into place.